cheap t post

-

30 Percent Chicken Mesh for Enhanced Fencing Solutions and Agricultural Applications

Exploring the Versatility of 30% Chicken Wire Chicken wire, also known as poultry netting, is a stap...

-

4 foot chain link gate

The Versatility and Benefits of 4% Foot Chain Link Gates When it comes to securing properties, defin...

-

Best Tomato Cages for Growing Healthy Roma Tomatoes in Your Garden

The Importance of Using Tomato Cages for Roma Tomatoes Growing Roma tomatoes can be an incredibly re...

-

5 ft high chain link fence

Exploring the Benefits of a 5% 20 ft High Chain Link Fence When it comes to securing properties, esp...

-

chicken wire 6ft tall

Chicken wire, often referred to as poultry netting, is a versatile and practical material that serve...

-

6ft chain link fence

Understanding the Benefits of a 6ft Chain Link Fence When it comes to securing properties, a 6ft cha...

-

6.5 ft t post bulk

Understanding the Value of 6.5 ft T Posts in Bulk Purchases When it comes to fencing and agricultura...

-

5-foot tall chain link gate for secure outdoor access and enhanced property safety

The Significance and Features of a 5-Foot Tall Chain Link Gate When it comes to securing properties,...

-

chain link fence tension wire

Understanding Chain Link Fence Tension Wire Essential for Durability and Stability When it comes to...

-

6x12 temporary fence panels

The Importance of 6x12 Temporary Fence Panels In various sectors, the need for security, demarcation...

Pharmaceuticals HEC is commonly used as a thickening agent and stabilizer in oral suspensions, tablets, and capsules Pharmaceuticals HEC is commonly used as a thickening agent and stabilizer in oral suspensions, tablets, and capsules

Pharmaceuticals HEC is commonly used as a thickening agent and stabilizer in oral suspensions, tablets, and capsules Pharmaceuticals HEC is commonly used as a thickening agent and stabilizer in oral suspensions, tablets, and capsules

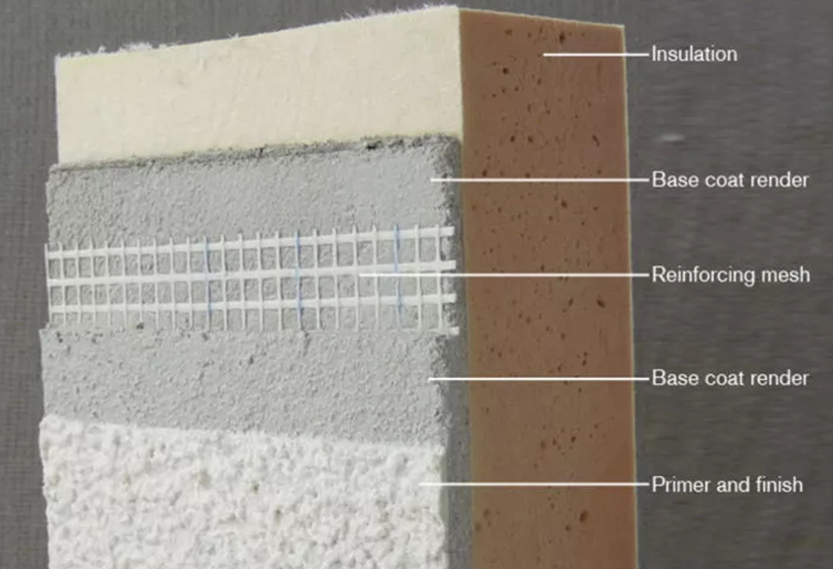

For instance, in the construction industry, latex adhesives are used for bonding tiles, roofing materials, and waterproofing membranes For instance, in the construction industry, latex adhesives are used for bonding tiles, roofing materials, and waterproofing membranes

For instance, in the construction industry, latex adhesives are used for bonding tiles, roofing materials, and waterproofing membranes For instance, in the construction industry, latex adhesives are used for bonding tiles, roofing materials, and waterproofing membranes Their expertise lies not only in the chemical synthesis but also in the formulation of HPMC grades tailored to specific applications, be it in construction materials, pharmaceuticals, food additives, or even personal care products Their expertise lies not only in the chemical synthesis but also in the formulation of HPMC grades tailored to specific applications, be it in construction materials, pharmaceuticals, food additives, or even personal care products

Their expertise lies not only in the chemical synthesis but also in the formulation of HPMC grades tailored to specific applications, be it in construction materials, pharmaceuticals, food additives, or even personal care products Their expertise lies not only in the chemical synthesis but also in the formulation of HPMC grades tailored to specific applications, be it in construction materials, pharmaceuticals, food additives, or even personal care products